High-Efficiency Particle Air (HEPA) filters are mostly used in environments such as clean rooms, operating rooms and other areas sensitive to contamination risk. The difference between the various filter designations like HEPA 11, HEPA 13 etc. indicates the particle size it’s designed to capture. HEPA filters are ideal for very small particles, measured in micrometers or microns and are represented by the symbol µm. To put particle size into perspective a human hair ranges in size from 17-181 microns in diameter, most allergy causing pollen is 10-40 microns, duct particles can be as small as 2.5-10 microns, bacteria are generally in the range of 0.3-5 microns and viruses, the smallest particles, range in size from 0.004-0.1 microns.

HEPA Filtration – How does it work?

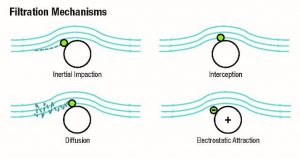

- Inertial impaction predominantly occurs on larger particles. Large particles have high inertia and as the air flows around the fibers, the particles continue along their trajectory and crash into the fibers instead of following the airstream.

- Interception occurs when the airstream carries particles within one radius of the fiber, causing a collision between the particle and the fiber, and trapping the particle in place.

- Diffusion affects very small particles; 0.1µm and under. Small particles continually bump into each other as they travel through the air, causing for a very chaotic or random zigzagging path. This motion is referred to as Brownian motion. Brownian motion causes particles to collide with fibers and become trapped.

- Electrostatic Attraction occurs when particles are attracted to the fibers by electrostatic adhesion. In HEPA filters, this mechanism contributes the least to the efficiency of the filter.

Particle Size & Efficiency

With an efficiency rating of 99.97% at 0.3µm, a common misconception is that HEPA filters do not remove particles smaller than 0.3µm. This is untrue because HEPA filters do not act like a sieve where particles above a certain size are prohibited from flowing through while smaller particles are allowed to pass through, but rather use the four different mechanisms of filtration to trap particles of varying sizes effectively.

Here’s a great detailed explanation here for the math geeks in the group. (Thanks to Price Industries for a LOT of engineering info and guidance.)

Work is underway in our testing to find the right balance of efficiency, sound attenuation, cost and HEPA level. While intellectually we’d like to see HEPA 14 used, it’s not really improving much as compared to HEPA 13, but it’s a lot bigger and more expensive. So today it’s looking like HEPA 13 is where we’ll start.